Lifetime Belt

THE NAME SAYS IT ALL

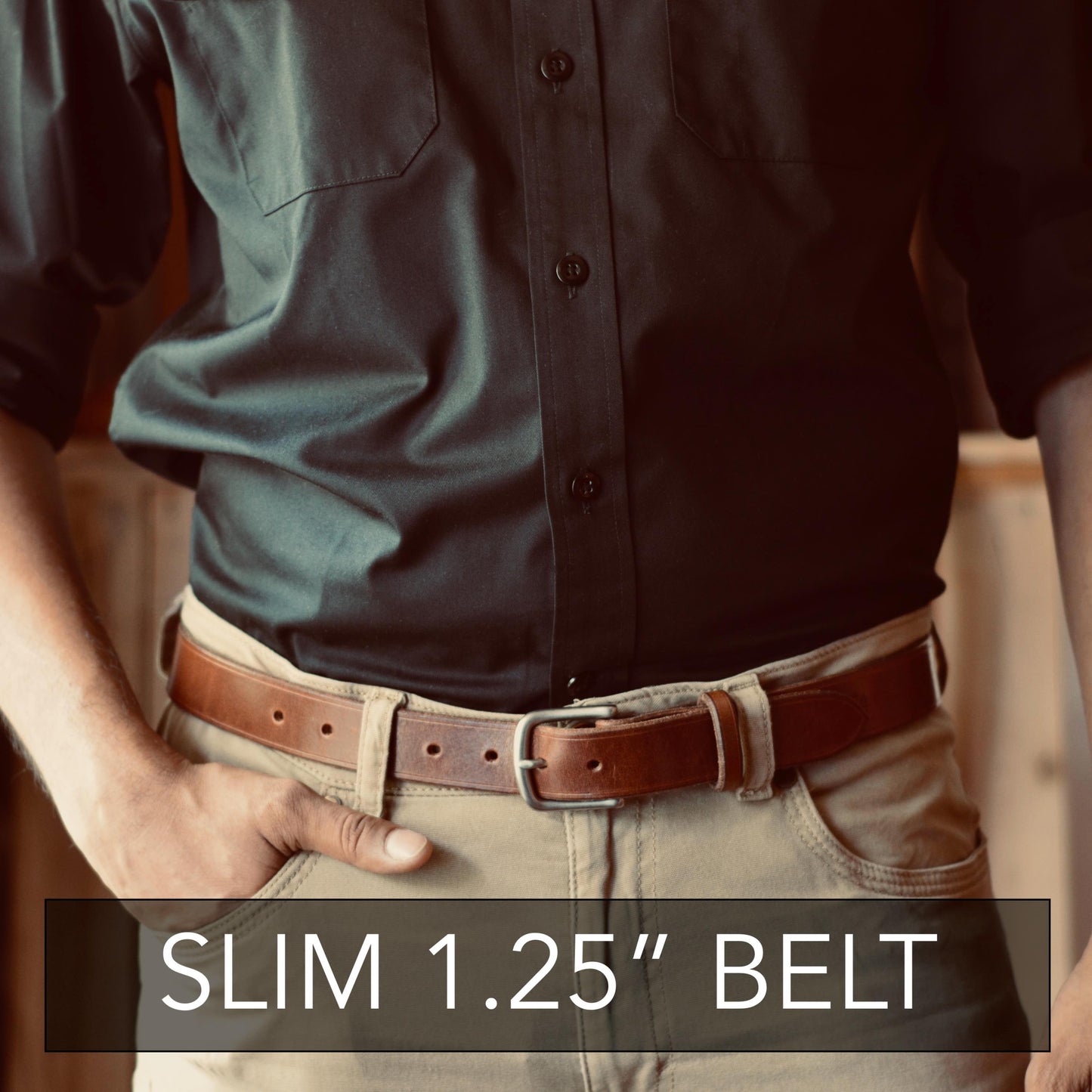

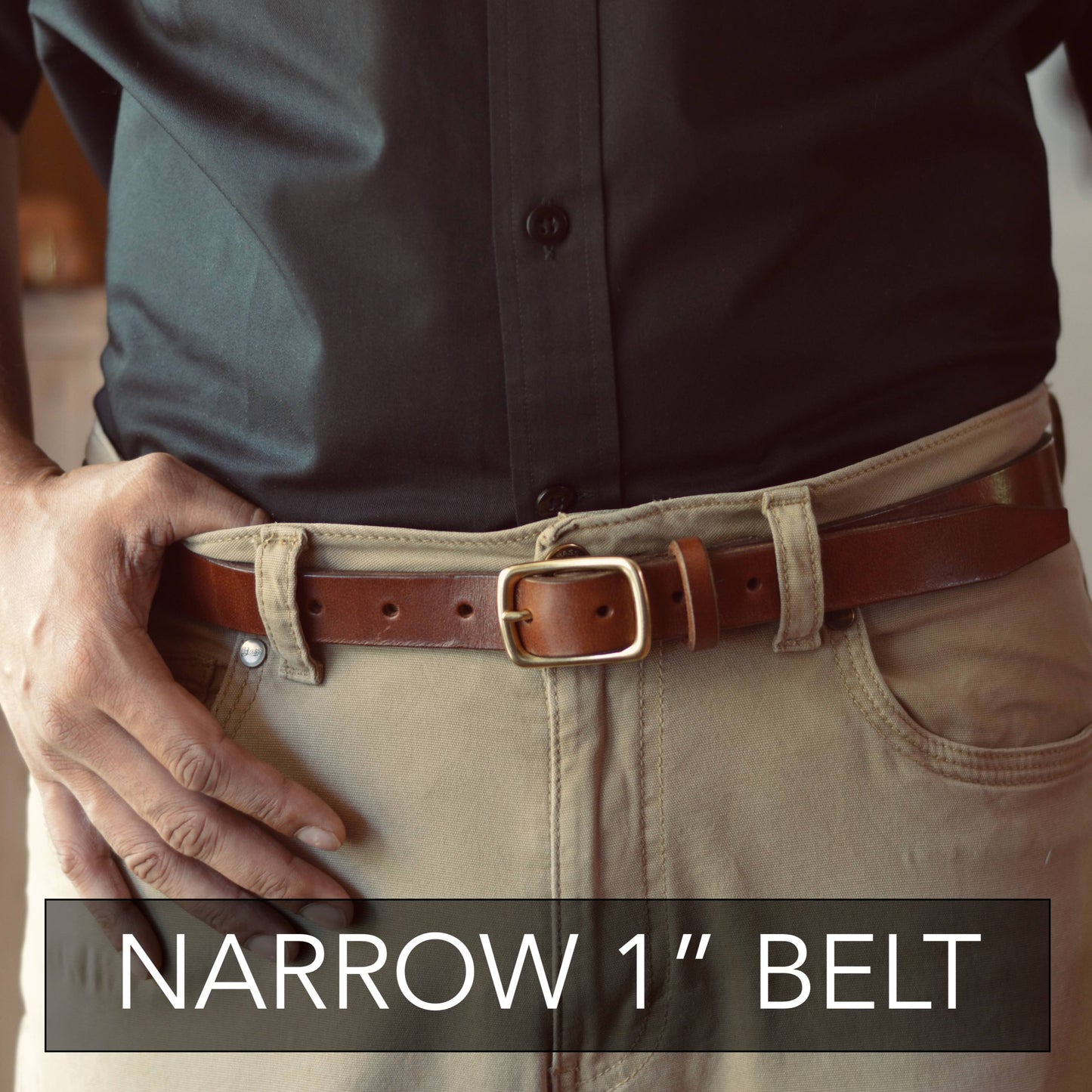

Imagine having something in your possession that will stand by your side your entire life. Something that's dependable and brings you joy everyday. The lifetime belt will fit into your life for exactly this reason.

Lifetime Belts with Solid Brass Hardware

Lifetime Belts with Solid Brass Hardware

These are rugged, casual belts. The leather used to make these belts comes from one of the most skillfully made vegetable-tanned leather in the world. 5 mm thick belts, made from leather that comes from the oldest running tannery in America. A leather that's quite rare to lay hands on.

The story behind this belt

Many moons ago, On a cold dark morning in New York City...

I decided to make a leather belt. A belt to end all future belts. A belt that was going to last me till I was in the ground, dead and buried. Good thick leather, solid hardware. Not much to muck up here unless you want to. At this point, I had been a hobbyist leather crafter for close to 6 months. Godbolé Gear had not been born yet.

The first belt I made in 2013. Picture taken in 2019, long before the belt went missing earlier this year.

I did make that belt. It endured harsh winters and cold rains of New York. Later, when I moved to India in 2014, it went through the heat and the incessant one foot a day rains in Mumbai. It did right by me for a long time, 2013-2023, until I went and lost it. Now it’ll be buried with someone else. Sucks.

It's now time to make a new belt - A tough belt that’ll handle a lifetime of abuse. A belt that will develop a rich and unique patina. All the tiny dents, scratches and coffee spills over the years will make a belt that will be unmistakably yours.

The older it gets, the better it will look. This is decidedly going to be a casual/semi-formal belt. Let’s not pretend it’s a dress belt. However, I am a little weird and would most definitely use it with a suit. You do you.

There's really just three things you need to make a good belt - get the right leather, get the right hardware, and make it right.

Alright now, let's take a look at how the finer details will play out, shall we?

Crafting for Longevity

making sure the lifetime belt is designed to 'not fail'

"Regular" belts fail in all sorts of ways. To address that, the first and most important thing we have done, is that we've selected the right kind of leather. Let's look at what else I have planned for your Lifetime Belt. I have incorporated simple yet powerful techniques - not often used in 99.9% belts out there, sometimes to cut costs, or at other times because of plain lack of know-how.

Over the years I have made close to 500 belts. Might not seem like much. But when you spend 4 hours making a single belt and then do it 500 times, you really get time to think about the function, design, why things are made a certain way, why things might break, what could be done better.

-

Maintaining Full Thickness

Most belt makers thin down (skive) the part of the belt that goes under the buckle. This section, where the leather is made thinner gets very weak over the years because it holds the buckle in place, seeing most stresses and it is thinner than the rest of the belt. It is one of the major sources of failure. It is not rocket science to loop a thick piece of leather over the buckle if you use the right techniques. But no one usually does it (a) because it takes longer, and (b) requires different techniques. Usually the skiving of leather is done in the name of comfort, however I did not suffer a single minute when I made mine without thinning the leather down. Lifetime belt will be full thickness.

-

Stitching - never across buckle, Always along the length

Some belt makers will stitch the buckle to hold it in place. Others will use rivets in addition to stitching, in case either one of those gives way. Redundancy is good. Except for one tiny problem that can break the belt. That stitching seam just below the buckle along the width is the single biggest point of failure. We will NOT be doing that. We always stitch along the length of the belt, in the direction of the pull. The thread is Tiger Ritza from Julius Koch, Germany, the gold standard in stitching. We hand stitch (saddle stitch) along one direction and then back stitch along it too, for good measure, This makes the rated strength of the thread 160 kg. There is no question of our thread breaking or a stitch coming loose.

-

Chicago Screws for Strength and Easy Swaps

Compared to rivets, Chicago Screws are much stronger. We will be offering the option of deploying Solid Brass Chicago Screws to hold the buckle in place on your belt. This will make the construction super strong.

Chicago Screws or Stitching? You choose. Durability-wise, either will work well on the Lifetime Belt. The advantage of only Screws, no stitching is that you can change buckles if you like! You get more flexibility for styling your belt, and the care and maintenance of the belt will become a breeze as you can screw and unscrew them with a screwdriver!

Locating Good Leather

Thick full grain leather that will brave the elements

The leather needs to be full grain, thick, strong, supple and should not stretch. Let’s get leather made from one of the oldest tanneries in America - Wickett & Craig. Wickett & Craig has focused, since 1887, on making some of the best full grain, vegetable tanned leather worldwide. That is quite literally all they do. The fact that most of their leather is used for making saddles and saddlery is a testament to its strength and durability.

We are bringing leather directly from Wickett & Craig, world-renowned makers of exceptional vegetable tanned leather since 1887. Pic Courtesy: Wickett&Craig Tannery, Pennsylvania

I chose Wickett & Craig, because I really like how their leather feels. Located in in the little town of Curwensville, Pennsylvania, they have a deep knowledge and understanding of their leather. Their master tanners and curriers have passed on their knowledge for generations since 1887. Their leather smells good, just how leather should smell - a woody and earthy smell that's not pungent.

And most importantly, they have the right type of leather that will make fantastic belts. 5 mm thick, vegetable tanned leather tanned just right to last a lifetime. Well cared for, this belt will last……an eternity.

In all seriousness though, the fact is that there was absolutely nothing wrong with my belt after ten years of use.

Watch Video

Our belts will be made with leather from one of the best tanneries in the world. This vegetable tanned leather takes six(6) weeks to make, vs chrome tanned leather that can be made in one day. Video Courtesy: Wickett&Craig Tannery

It will be an understatement to say that these belts are special. The leather is from Wickett & Craig, one of the most renowned tanneries based in America. These folks have been making vegetable tanned leather since 1887. Many specialty leather goods brands from America and Europe turn to them for leather. Tanner Goods, Florsheim, Filsons and Nicks Boots - to name a few.

What is Harness Leather?

traditionally used for saddlery, makes excellent belts

The Harness leather is very special. It’s got all the oils and waxes that the leather would need for at least a few years of getting drenched in the rain. It's also more supple which means the belt “breaks-in” to your waist quicker. Easier to wear. Harness patina’s well too.

Due to the high oil and wax content in the leather, Harness leather also takes on dings and dents more readily than other leathers, developing a very striking character over time.

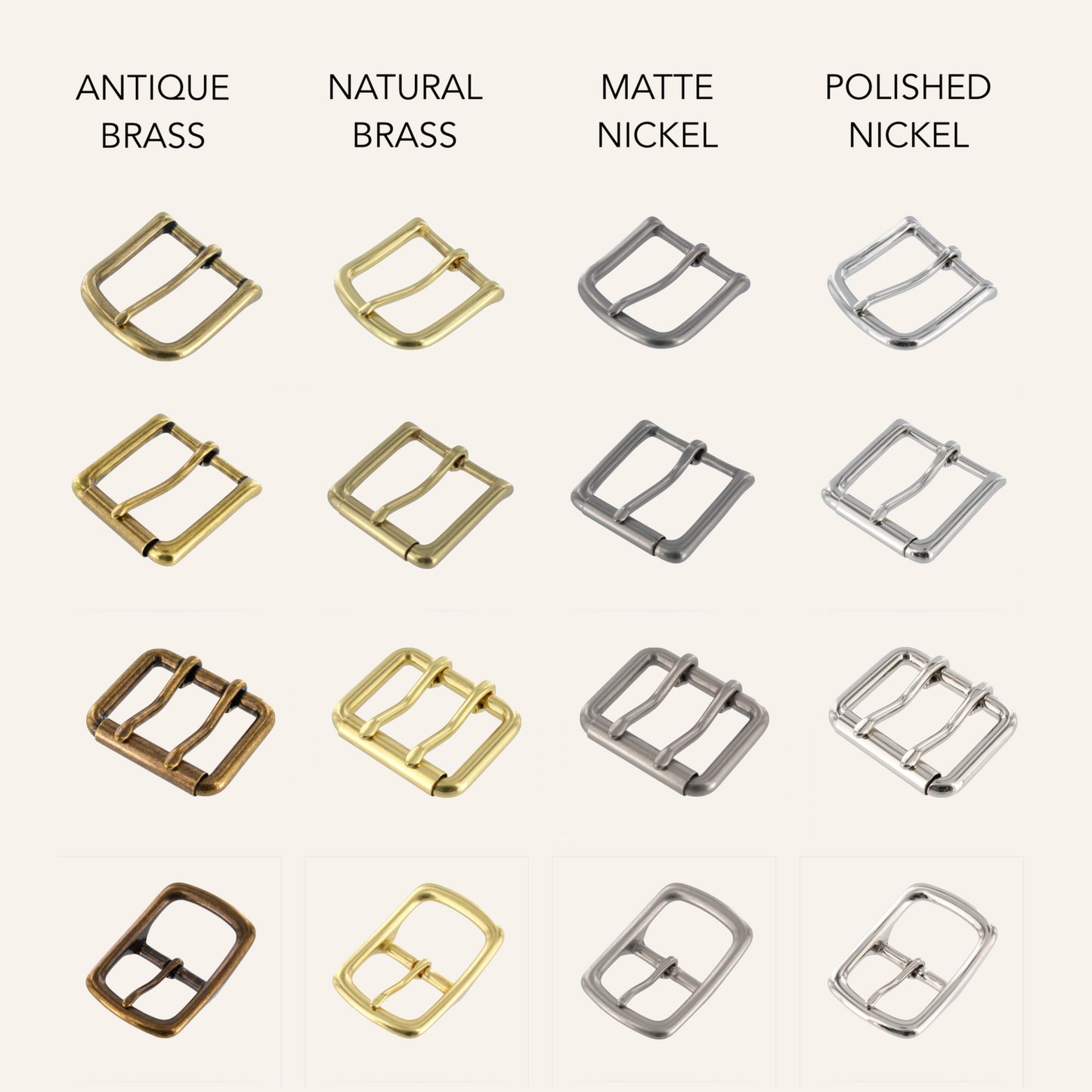

Selecting Good Hardware

Solid brass, made right

We are going to go with good-old, field tested, solid brass hardware. The kind that is exceedingly rare to find in most name-brand belts these days. The hardware we use feels heavy. It is heavy for a good reason. The reason is Solid Brass.

We are going to go with good-old, field tested, solid brass hardware. The kind that is exceedingly rare to find in most name-brand belts these days. The hardware we use feels heavy. It is heavy for a good reason. The reason is Solid Brass.

These buckles are masterfully cast with zero pitting. Each buckle is hand polished and laquered to prevent corrosion.

Solid Brass Buckles from our Newburyport, MA supplier in Antique, Gold, and Silver Finishes. Each buckle is perfection personified.

Most hardware these days is made from Zinc alloys. Looks fine, works well, until it doesn’t. One fine day zinc hardware will just break with no notice. A brittle failure.

We source our hardware from a 4th generation, family owned and operated business based in Newburyport Massachusetts. They have been consistently delivering quality for over 78 years! We have sourced all our hardware from them for the last 9 years. They have 100% reliably delivered excellent hardware. They are good.

A word about Chicago Screws - In all pictures, you can see what looks like brass rivets on the belts. These are actually Chicago screws. They are also made of high grade brass. These are as strong, if not stronger than rivets. While being very secure they can be unscrewed with a screwdriver! So if you want some variety and want to swap out your buckle with a new one, it's super quick and easy.

Common Questions

Can you ship to my country?

Yes, most likely we can. The cost of shipping goes down with multiple items ordered. So, for international shipping, email us ( contact@godbolegear.com ) your pin code/zip code for the most accurate quote on shipping rates.

Can I order after the Campaign Ends?

No, it doesn't work like that! The earlier you place an order, the higher the chance of a successful campaign. This enables us to import leather in larger quantities, making it viable for shipping. No new orders will be accepted after May 1st. On May 2nd, we will place an order with the tannery in USA based on number of orders received.

Can I change my choice of colour or belt after I place my order?

Yes, as long as you do so before April 30th. If you have an additional colour request you'd like to make, email us at contact@godbolegear.com